The BR-3.1 sickle-bar is designed for mowing annual and perennial crops cultivated in pure form and in mixed crops both on arable land and on meadow lands and cultivated hayfields. The BR-3.1 sickle bar is unified and can be supplied for equipping modular mowers such as the three-section mounted mower KPR-9 or KPR-6 and their modifications, aggregated by an energy vehicle or tractor.

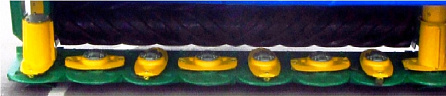

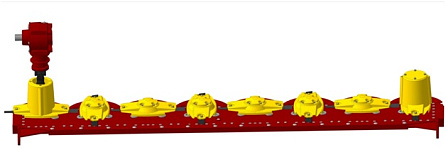

The design of the BR-3.1 sickle bar has a cutting device with eight rotors, which are equipped with short screw-shaped plate knives, which allows to increase their service life. The rotor discs and the support shoes of the sickle-bar are thermally hardened to increase their working life.

The drive of the working elements of the cutting beam is carried out from the drive shafts of the mower through a conical gearbox and a telescopic gimbal transmission.

In pairs, the rotors rotating towards each other betray the movement of the knives and move the mown plants through the sickle-bar.

Drum casings are installed on the extreme rotors of the cutting beam, which allow for preliminary narrowing of the flow of the mowed mass of plants.

The saddles are made of wear–resistant material and provide protection of the lower panel of the cutting bar from abrasion, rotor discs and knives from accidental contact with foreign objects. To increase the height of mowing grasses from 50 mm to 100 mm, two wide shoes are additionally installed under the gear beam of the cutting beam.

Advantages of the BR-3.1 cutting bar:

- the diameter of the rotor discs has been reduced in comparison with the basic version, which reduces their protrusion beyond the leading edge of the cutting beam and ensures protection when hitting rocks;

- the oval shape of the rotor discs has been increased, which improves the patency of the beveled mass and reduces the likelihood of a direct impact in contact with foreign objects;

- the rotor discs do not protrude beyond the leading edge of the cutting beam and provide protection when hitting rocks;

- the rotor discs and the support shoes of the cutting beam are thermally hardened to increase their working life;

- 2 screw knives of shorter length are pivotally mounted on the rotor discs in comparison with the basic version, which practically eliminates their destruction when hitting stones;

- the circumferential cutting speed of the knife 80 m/s ensures the best cut quality;

- bearings with increased load capacity operating in an oil bath are used;

- drum casings are installed on the extreme rotors of the cutting beam, which allow for preliminary narrowing of the flow of the mowed mass of plants;

- reflective segments are installed between the shoes and in the front of the cutting beam to protect the gear beam and rotors from damage, as well as contributing to better cut quality.

|

The name of the indicator |

Meaning and characteristics |

|

The width of the grip, m, |

3.1 |

|

Overall dimensions, mm |

|

|

- length |

3200 |

|

- width |

700 |

|

- height |

400 |

|

Weight (without gearbox), kg |

300 |

|

Number of rotors, pcs. |

8 |

|

Number of knives, pcs. |

16 |

|

Circumferential cutting speed of the knife, m/s |

80 |

|

Rotation speed of the rotor discs, min-1 |

3000 |

|

Nominal diameter of the rotor for knives, mm |

512 |

|

Working speed, km/h |

6-15 |

|

- height |

|

|

Cut height (with additional shoes), mm |

50 (100) |

|

Losses, % no more |

2 |

Bobruiskagromash Holding Management Company Open Joint-Stock Company offers agricultural producers leasing services for agricultural machinery

You can get more detailed information and order equipment by calling:

You can order goods in the region you are interested in from our dealers